Caberra Solutions

for Pharmaceutical and Food Industry

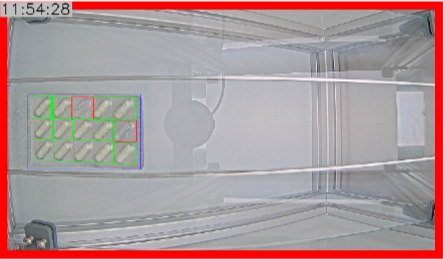

Detect Quality issues in real time

Caberra’s AI-driven systems monitor production processes in real-time, swiftly identifying any anomalies or defects. Upon detection, the system immediately triggers corrective actions—either automated or human interventions—and logs the data for post-production analysis. This information is seamlessly transmitted to other systems and displayed on real-time dashboards, facilitating prompt decision-making and continuous improvement.

Proactive Prevention of

Quality Issues

By employing AI to automatically assess the quality of production outputs, Caberra enables the early identification and resolution of potential issues. This proactive approach ensures that products meet stringent quality standards, reducing waste and enhancing overall efficiency.

Reduction of Product Returns

With Caberra’s intelligent quality control, defective products are identified and removed from the production line before reaching the packaging stage. This preemptive measure ensures that only products meeting quality standards are dispatched to customers, thereby minimizing returns and enhancing customer satisfaction.

Custom product built

Integrated AI system using Caberra Detect.

Construction to docl with the manufacturing environment of the customer (air pressure to expedite identified problematic parts).